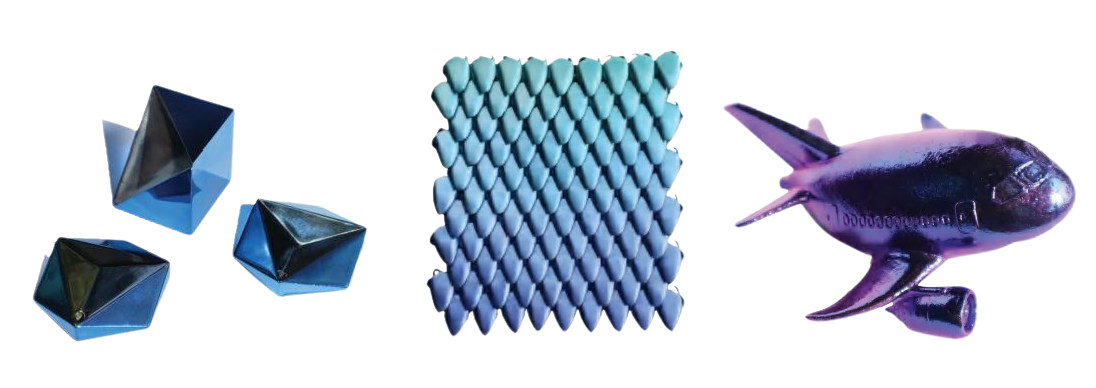

SLA

Ideal for high-detail prototypes, visual models, and complex geometries.

Smooth surface finish and excellent dimensional accuracy.

Parameters

Layer height: 0.05–0.1 mm

Typical tolerance: ±0.1–0.2 mm

Materials: Standard resin, ABS-like, Tough, Clear

Best for: housings, cosmetic parts, concept models

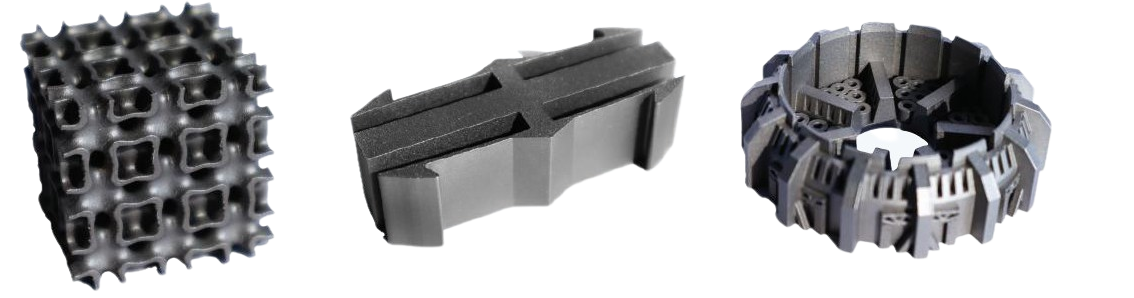

SLS

Best for functional parts requiring durability and mechanical performance.

No support structures, enabling complex geometries.

Parameters

Layer height: 0.1–0.15mm

Typical tolerance: ±0.2–0.3mm

Materials:PA12,PA+GF,PP,TPU

Best for:brackets, robotics parts, mechanical assemblies

Metal 3D Printing(SLM / DMLS)

High-performance metal parts for engineering, tooling, and end-use applications.

Supports stainless steel, aluminum, and titanium alloys.

Parameters

Layer height: 0.03–0.05 mm

Typical tolerance: ±0.1–0.3 mm

Materials:316L, 17-4PH, AlSi10Mg, Ti6Al4V

Best for:high-strength prototypes, lightweight structures

Titanium

High Strength, Tunable, and Low-Cost

Up to 2× the strength of standard CP-Ti and above conventional Ti-6Al-4V

REcycled& 90–95% material utilization, up to ~30% cost reduction

R-T1 ≥ 850 MPa UTS with 18–25% elongation

strength/ductility tailored via O/N control and pre-deformation

cold-forming powder process with low energy consumption

CNC Machining

Production-grade parts with tight tolerances and high quality finishing.

Suitable for both metals and engineering plastics.

Parameters

Tolerance: ±0.05 mm (depending on geometry)

Materials:Aluminum 6061/7075, POM, ABS, PC, PMMA

Best for:functional prototypes, enclosures, brackets

SAMPLE

Crafts

Souvenirs

Medical Devices

Industrial Components

Item

Typical materials

Surface finish

Strength & durabilit

Dimensional accuracy

Min. wall thickness

Best for

Not ideal for

Typical lead time

SLA Resin Prototyping

Standard, ABS-like, Tough, Clear resins

Very smooth, good for cosmetic parts

Moderate; good for light functional use

±0.1–0.2 mm (typical)

0.8–1.0 mm

Visual models, housings, show parts

Long-term load, high temperature

1–3 days

Process Comparison

SLS Nylon (PA12

PA12, PA12 + GF

Slightly rough, matte, can be tumbled

Good impact and fatigue resistance

±0.2–0.3 mm (typical)

0.8–1.0 mm

Functional prototypes, mechanical components

Mirror-like surfaces, transparent parts

2–4 days

Metal 3D Printing

316L, 17-4PH, AlSi10Mg, Ti6Al4V

Fine but grainy metal surface, needs finishing

Very high strength and temperature resistance

±0.1–0.3 mm, geometry-dependent

0.6–1.0 mm

High-value metal parts, complex internal features

Very low-cost prototyping, very large parts

4–7 days